Condition Monitoring – Don’t Have Stored Fuel Without It Part 3

This summer we hosted a webinar called Condition Monitoring for Stored Fuels. During the webinar we explained what condition monitoring is and the...

8 min read

Erik Bjornstad : Oct 5 2018

This summer we hosted a webinar called Condition Monitoring for Stored Fuels. During the webinar we explained what condition monitoring is and the key elements of condition monitoring, why it’s important, and how you should be doing it. You can watch the recording of the webinar here, or you can read the transcript in this five-part series.

Thanks very much for joining me for our webinar today, which is on, "Condition Monitoring: Don't have stored fuel without it," which is, of course, something that I stole from the old American Express marketing. I am Erik Bjornstad. I'm the Technical Information Director here at Bell Performance. 2018 has been a big year for the industry, for everyone across the country who has stored fuel, which is a lot of people because the changes in the industry that have been kind of fomenting over the last three or four or five or more years, those are now starting to come to roost. People are finding that they need to change their approach when it comes to managing their stored fuels, especially if they manage any kind of mission critical stored fuels.

In our time together today, we are going to talk about the really important issue of condition monitoring of stored fuels. By the time we leave, the goal is that you'll leave here with a better understanding of what this thing called condition monitoring is all about. That means we want you to understand better the what's and the why's and the how's of the subject. We are going to start with some context on the basics of fuel microbiology before jumping into what condition monitoring is, why it's important, what considerations you need to think about when you're planning what you need to do about it. That means when we talk about that kind of thing, we have to talk about fuel sampling. How should you be sampling your fuels? How should you be handling those samples? Because those are all important factors to get us to our end goal for mission-critical fuel management. That end goal is making sure that we know the true condition of our stored fuels so that we know if we need to act or not.

As we look closer at the subject, one thing we should realize is that when it comes to microbes and their role in the world around us, things are rarely as simple as they might seem or as simple as we might want them to be. Let's dive in by taking a brief overview of this thing called fuel microbiology, which is going to set the stage for talking about the why's of condition monitoring. Now, when we talk about this kind of thing, we usually start out by laying out some kind of justification for why we need to be talking about it. That means we need to be talking about what this problem costs businesses and fuel uses across the country.

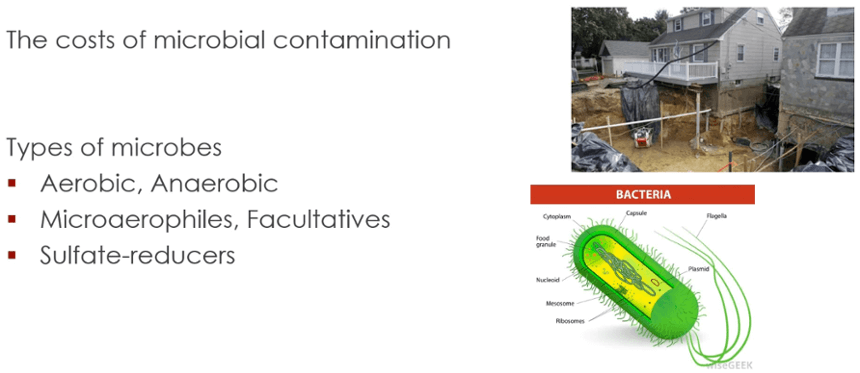

Now, those costs when you're talking about something like microbe related corrosion, which is a term that you will hear a lot, what they call MIC - microbe related corrosion - those costs are pretty substantial both on a national level where countrywide costs are probably over 300 billion dollars a year. They were 270 billion 10 years ago. Not just on a national level but the ground level to where, let's say that you're a C store, a gas station and you have slow flow rates because of blockages, filter blockages because of microbial activity in your stored fuel. You can lose a five to 20% of your fueling revenue because of those slow flow rates. Then you have catastrophic costs like if a storage tank leaks, again, because of corrosion issues, you're looking at at least $200,000 to $500,000 per site.

As you can see, that's going to end up costing them a fair bit of change there. It's clear if left uncontrolled, microbial contamination in fuel systems can lead a number of expensive problems.

What about the microbes themselves? Types of microbes, of which there are many different types. Microbes, we all remember from school, they're single-celled organisms, they're too small to be seen with the naked eye, and there are all different kinds, right? There are bacteria and fungi, which are the ones that get invited to all the best parties, of course, fungi, viruses, algae, protozoan. You won't find all of these kinds in every single place. I mean, it's pretty rare to find like protozoa or even algae in fuel systems. When we talk about fuel microbiology, we typically concentrate on bacteria and fungi.

Now, even among those two broad categories, there are subcategories that are supposed to reflect what those kinds of bacteria need to grow and how they interact with the environment around them and what they do to the environment around them. Some of them are up on the screen, aerobics versus anaerobic. That relates to one needs a lot of oxygen to grow, and one actually needs an oxygen-free environment. There are microaerophiles which are the ones that need some oxygen, but not too much. There's what they call facultative, which are ones that actually consume oxygen and help create an oxygen-free environment so that other kinds of microbes can grow. There's also a major class of bacteria called sulfate-reducing bacteria or SRBs, and these are a major problem when it comes to corrosion causes in storage tanks.

Now, in a given fuel tank, you may have thousands of different kinds of microbes, and they all really require the presence of each other in order to grow and thrive. They live almost symbiotically. That's why if you talk to a microbiologist, they'll talk about a microbial colony being almost like its own ecosystem because there's so much going on in there.

Now, there are so many microbes on us and around us, it is virtually impossible to be microbe-free in any given situation except the very limited amount of sterile areas. When you're managing fuel, and you're dealing with stored fuel wherever you're at, the goal is never to be microbe-free because you can't be microbe-free. The goal is always to have a manageable level, a manageable level of microbial presence, that is the key. The question that we'll dig into more later is what is that a manageable level? What those manageable levels are?

Consider that in drinking water, the water that you get from your tap, or whatever treated water that's safe to drink, it is not uncommon for there to be between 10,000 and up to 1 million microbes in every milliliter of that water. That's not every ounce or cup that's almost like every drop. Now, if you go to the water that's at the bottom of a storage tank, you take that water bottom sample, it can be up to one billion microbes per milliliter. It should be easy to see there are so many microbes surrounding us everywhere we go, every second of every day. Nobody should ever be surprised when they find them pretty much anywhere they look.

That, of course, includes fuel systems and storage tanks. Since we find microbes in fuel systems and storage tanks all the time, it's fair to ask the question of how they tend to get in there. Apart from the fact that they're already present in the environment around us. When you ask the question how microbes get in the fuel systems, that's really two questions - how do they get into the storage tanks, the end user storage tank, so to speak, and how do they get and how do they progress along the fuel distribution system that's more upstream of that.

For end-user storage tanks, there are lots of ways that microbes can get in there because anything that enters the storage tank is going to have some level of microbial growth associated with it. You're talking about water ingress; you're talking about even simple water vapor, dust from the air that comes in and out of the tank. Definitely from anytime you get a fuel drop. If you're at a terminal and you have a large tank that's got a floating roof, that floating roof oftentimes scrapes things down from the shell into the fuel inventory. There's plenty of ways for microbes to get into storage tanks. Now, with the distribution system that's upstream of that, you start from the standpoint that when the fields put together at the refinery, it starts from a sterile standpoint because you've got extremely high temperatures that are involved in that and so you do start out with the fuel being sterile. But it's only sterile for a pretty short period of time because it's got to go into various kinds of bulk tanks which are not sterile.

Then, if it gets transported in a ship or a pipeline, those are not sterile by any means either. Consider that if you get fuel that's aggregated at a terminal or some kind of distribution point and it might be aggregating fuel from x number of refineries, 50, 6,000 other refineries however many that is. If one of those refineries has a microbial presence in one of its tank, what do you think that that microbial presence is going to do? It's going to get aggregated with all the rest of the other fuel from the other refineries. It's pretty easy to see that we should never be surprised when we find microbes in fuel because it's virtually everywhere. Now ultimately, we're most concerned with the microbial presence in the storage tanks.

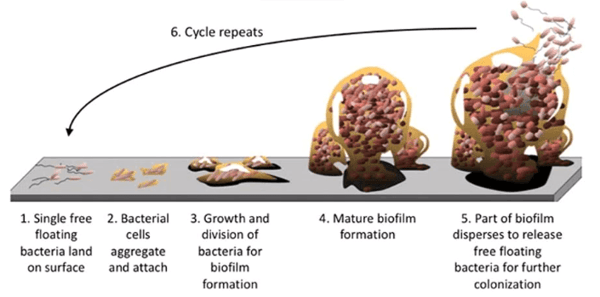

We ask the question, where do microbes like to live in fuel systems and storage tanks? Now usually, I should say in the past, whenever we've talked about microbes in storage tanks, we've always talked about how microbes need free water to grow, and you have free water phase at the bottom, and then you have fuel on top and you have an interface in between so microbes like to live at that interface. While that is true, that is not the preferred place for them to live. They actually like to live best in biofilm secretions and biofilm layers located on solid surfaces. Typically, when you look into a storage tank that has microbial presence, you're going to find a certain amount of biomass and biofilm in it, but the biofilm is not typically evenly distributed within any given storage tank because there's always going to be areas where the microbes tend to like to grow more than in other areas because it depends on what the given kinds of microbes prefer to use when they're growing.

Contrary to our perception, when you look at biomass, or you look at a mass of microbial slime, these biofilms are not what they call “uniform.” They're not simple, they're actually complex structures, and they have complex combinations of microbes that live in them. They can have significant variance in their thickness too. I mean, if you look, if you took a camera and you look inside of an underground storage tank and you saw a layer of biofilm, it would look like a layer of biofilm to you, but if you could actually get down and measure it and start to analyze it, what you would find is that biofilm patches within storage tanks can have significant variance in their thickness even within a short or relatively close distance from point A to point B.

Now, why do we bring this up? Well, this is going to relate to the point that we're going to make later when we talk about sampling. When we talk about the fact that sampling helps determine what you see from a tank, and that if you're sampling biomass or biofilm in order to try and get a picture of your microbial content, and you take a sample from point A, and then you take another sample from point B that's a foot to the left of it, there can actually be a significant difference in the picture that you're going to get when you analyze both samples because microbial presence can vary significantly from point A to point B even within just one specific area of biomass.

Think about the number of microbes that can live in biomass, right? If you have a one-millimeter thickness of biofilm, a one-millimeter thickness of biofilm is typically about a hundred times the size of most fungi organisms and 500 to 1000 times the size of most bacteria. When you're putting that in perspective, it should be obvious that it does not take much biofilm to be able to be home to a whole heck of a lot of microbes. These biofilms are really great environments for different microbes to grow in because many times, the environment that's inside of the biomass is significantly different than the environment that's outside, especially with respect to things like the pH, the oxygen level, the sulfur content. If you have certain kinds of microbes that prefer lower oxygen or greater sulfur content or different kinds of pH, those kinds will grow a lot better inside of biomass than outside.

The implications of all this detail for sampling is that if you, what I said earlier, if you record a number of microbes from a sample of biofilm, you have to ask yourself while you're doing this, you have to always be asking yourself how representative is the sample that I'm looking at. Because when you have a biofilm, you have the perfect scenario for when you need a thousand different species of organisms all requiring different levels of different things to grow and all depending on each other, the existence of each other alongside them in order to live life to the fullest, so to speak.

Read part 2 here.

Watch the full presentation below:

This summer we hosted a webinar called Condition Monitoring for Stored Fuels. During the webinar we explained what condition monitoring is and the...

This summer we hosted a webinar called Condition Monitoring for Stored Fuels. During the webinar we explained what condition monitoring is and the...

This summer we hosted a webinar called Condition Monitoring for Stored Fuels. During the webinar we explained what condition monitoring is and the...