The Hybrid Approach To Stored Fuel Care

Don’t Settle For An Incomplete Solution – Get The Hybrid Approach To Stored Fuel Management

Plugged filters, free water, darkened fuel and corroded tanks from microbes running unchecked in fuel storage tanks. So, what is the better solutions for these issues - chemical treatments or mechanical cleaning? Actually, the best (& most complete) solution is a combination of industrial-grade chemical treatments and properly executed mechanical processes, depending on the issue. Because the stored fuel that companies rely on to operate isn’t what it used to be, you can’t use the “same old” approach when it comes to solving problems.

Neither chemical nor mechanical solutions are the best and most complete answer for every likely scenario for fuel care. There is no such thing as “one size fits all” fuel maintenance.

Using the proper industrial-grade chemical fuel treatments can do some things very well, like killing microbes or stabilizing stored fuel quality. But they can’t do everything by themselves. And anyone who tells you they can is trying to sell you a bill of goods.

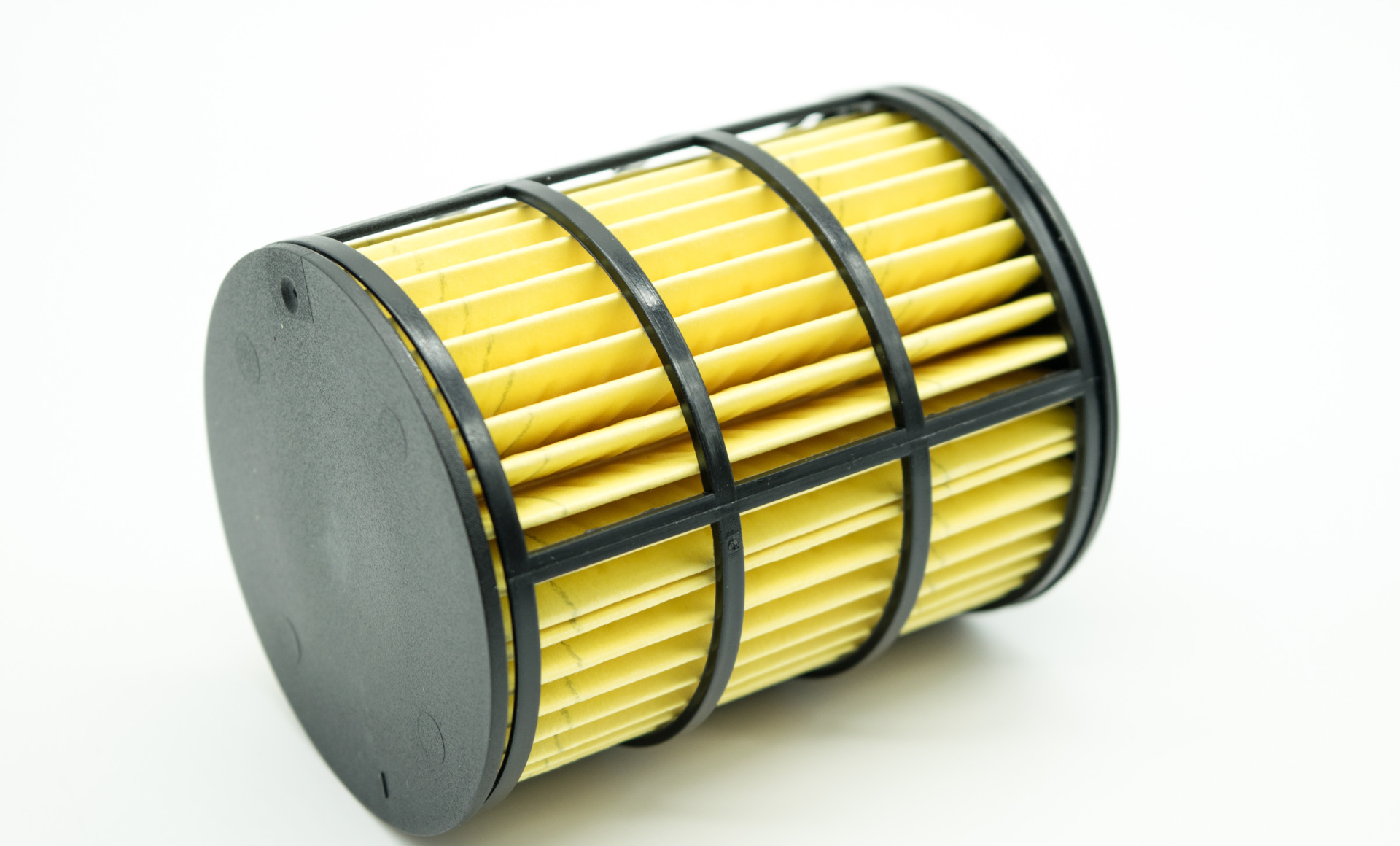

On the flip side, mechanical processes like fuel filtration are effective at important things like removing free water and cleaning out fuel tank sludge. But they do nothing for the root causes to keep the problems from coming back.

Fuel Testing Is The Overlooked Third Arm

All of this also points us to another essential fact - you can use both of these treatments yet still not be in the clear. There's a third element you need to include. Without some kind of fuel testing, it’s impossible to know 1) which solution you need the most and 2) whether the solution you used actually did what you wanted it to.

Not all kinds of testing are equally useful. There’s testing for fuel specifications to diagnose problems and infer solutions. Perhaps most importantly, there’s the need for microbial testing, both at regular intervals (preventive monitoring) and during problem resolution.

In fact, you have very little chance of successfully solving microbe-related fuel problems if you don’t incorporate microbe testing to properly diagnose or confirm the problem. Luckily, stored fuel users have some state-of-the-art options for doing this.

Customizable Fuel Care Plans

The Hybrid Approach to fuel maintenance combines the best industrial-grade chemical treatments with essential mechanical cleaning processes coupled with industry-leading fuel testing to produyce unparalleled world-class fuel maintenance.

Bell Fuel & Tank Services brings to its customers the perfect combination of all three of these best practice pillars, in a customizable plan that fits their needs and budget.

- Highly effective mechanical fuel cleaning to remove water, sludge and biomass.

- The right chemical treatments – biocide, tank corrosion inhibitor, fuel stabilizer and more - to solve problems and prevent them from coming back.

- Diagnostic fuel testing for a reliable assessment of the problem and an accurate assessment of whether it’s been solved.

- Microbe monitoring and testing solutions to properly confirm that fuel problems have been solved while predicting if/when problems may arise in the future.

The Hybrid Approach to fuel management ensures you get the best possible solution for the best possible cost. And it also ensures that you stay in control of knowing the health and readiness of your fuel at all times. How does peace of mind and no more surprises sound?

Helpful Resources

Fuel Changes and How They Affect You

Webinar

What's My Fuel Health Score?

Webinar

Top Ways Microbes Cause Fuel Headaches

eBook

The Fuel Additive Buying Guide

eBook

Fuel Checklist for Stored Fuels

Checklist

Essential Fuel Tests

Document

Fuel Tests You Need To Know About

Webinar

Tank Health Signs

Ebook

Tank Treatment - Half an Approach

ebook

FTS Product Quick Reference Chart

Checklist

Fuel Storage on our Commercial Blog

6 min read

Joint Commission and SPCC Compliance: Where Fuel Tank Requirements Overlap for Hospitals and Data Centers

Erik Bjornstad: Feb 18, 2026

7 min read

Fuel Tests That Actually Predict Failure: Understanding ASTM D6469 and Microbial Testing

Erik Bjornstad: Feb 12, 2026