Aviation Has A New Partner For Solving Fuel Problems

Almost every sector in our economy that uses fuel has had to grapple with a hard truth - things aren’t what they used to be with their fuel. But this...

In any system used for fuel distribution or fuel storage, you are most likely to find microbes living on physical surfaces (like tank walls) and at interfaces between fuel and free water. When on surfaces, microbes live in and behind biofilm formations - slimy growths that can house entire living ecosystems of microbes. It is this slimy growth that may also turn into particulate that is suspended in fuel and blocks filters.

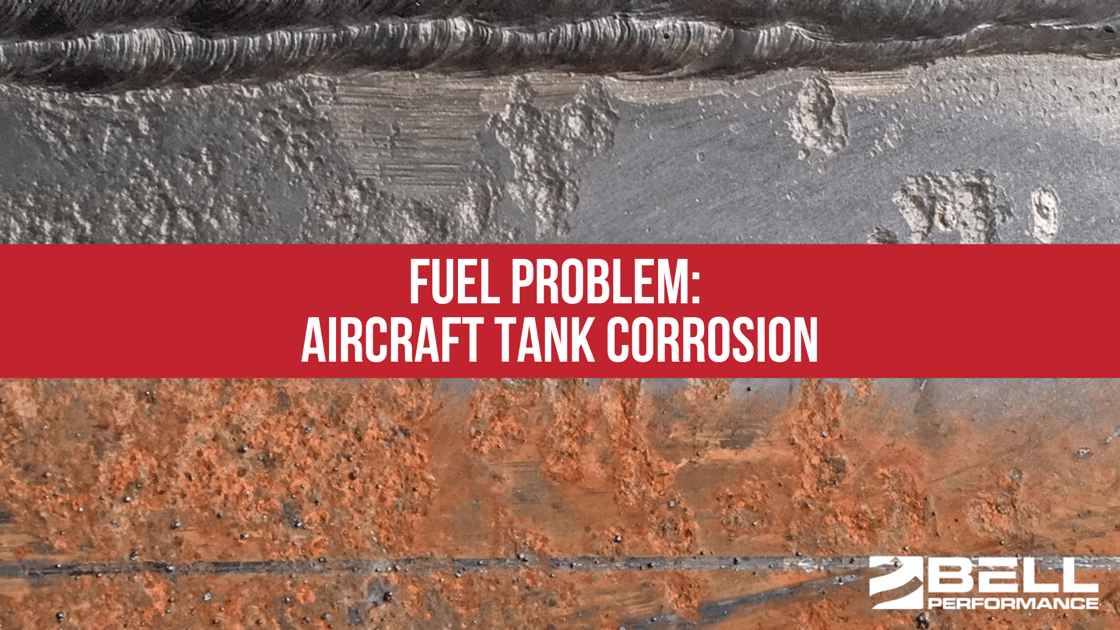

Starting about 20 years ago, observers across a variety of sectors noted an upswing in “MIC” - microbially induced corrosion. The microbes responsible for this corrosion do so by a variety of mechanisms - some simple, some more complex. Specific to planes, aluminum structures in aircraft wings become corroded through the action of acids produced by microbes that live in these biofilm formations.

Starting about 20 years ago, observers across a variety of sectors noted an upswing in “MIC” - microbially induced corrosion. The microbes responsible for this corrosion do so by a variety of mechanisms - some simple, some more complex. Specific to planes, aluminum structures in aircraft wings become corroded through the action of acids produced by microbes that live in these biofilm formations.

MIC damage in aircraft and aviation systems can be recognized by signs of pitting or etching on surfaces. This damage may develop at a surprisingly fast rate. So monitoring is an essential element of staying ahead of this problem, all the while realizing that these metal structures in aircraft that are attacked by microbes aren’t so easily accessible for this monitoring.

That’s why it’s so important to monitor the microbiological contamination levels of the fuel itself, which is best done through regular fuel testing with a suitable testing procedure like ATP-By-Filtration. The industry seems to concur - IATA recommends routine microbial testing, as do the AMMs for many leading aircraft manufacturers - Airbus, Boeing, Gulfstream, and others, both noncommercial and commercial.

Almost every sector in our economy that uses fuel has had to grapple with a hard truth - things aren’t what they used to be with their fuel. But this...

For many years, no matter what industry you were in, microbial fuel contamination was a guessing game. We all know microbes are out there, and it’s...

This blog post isn't about quite what you might think. We're talking about microbial testing. Today's stored fuels require a lot more upkeep than the...