Stored Fuel Testing Part 1: What you need to know

As a service to our customers, dealers and friends, Bell Performance hosts quarterly webinars on fuel topics of interest to their friends and their...

As a service to our customers, dealers and friends, Bell Performance hosts quarterly webinars on fuel topics of interest to their friends and their customers. This is Part 4 of a transcript of one of these recent webinars held on Fuel Changes & The Impact They Have On Your And Your Business. If you would like to watch the archived presentation, please click here. If you would like to read part 3, please click here.

Click here to jump to the first post in the series.

Continued from Part 3

You remember when we were talking about fuel users and we had the generator, we had the black smoke picture and I talked about system operation and the possibility of systems not operating the way that they should? This is where we circle back and talk about that a little more.

Stored Fuel for Emergency Use

Consider places that store fuel for emergency use like hospitals, like businesses, like telecommunications businesses, public utilities, places that have to keep going and cannot have their systems shut down, so they have backup systems restored fuel.

The nature of stored fuel, what we call emergency use fuel is that they tend not to be checked very often. The fuel is there because they might need it at some point, but they don't know when they're going to need it. They just know that when they need it, it has to do what they need it to do. It absolutely must. There's a very, very high value placed on that stored fuel performing properly when it's called on to do so. As we have implied, the nature of emergency is, they don't know when that fuel is going to be needed.

Because of human nature, unless there is a rule in place that says, you must check your tank every month, you must check the tank, test the fuel, do whatever x number of times within a year. Unless there's something directing people specifically to do it, people tend to leave that alone. It's out of sight, it's out of mind.

What you get is, you get problems that arise when emergencies happen and the fuel in that tank hasn't been checked. You get a higher chance of what we'll call critical system failures.

What comes to mind is Hurricane Katrina back in 2005, then the more recent superstorm Sandy that pummeled the northeast. In both cases, there were emergency systems that had significant amounts of fuel that had not been checked because they didn't have any reason to check them. It was out of sight, out of mind. They just assumed that it was going to do what they needed it to do. There were publicized problems. There was a hospital that did not have its generators, it's essential backup generators work properly. I believe there were some human casualties involved with that.

Again, this type of stuff, emergency use fuel is out of sight, out of mind. You don't know when you're going to use it and if there is a problem, unless you're checking it, you won't know that it's not going to do what you need it to do until it is too late.

Microbial Build Up in Storage Tanks

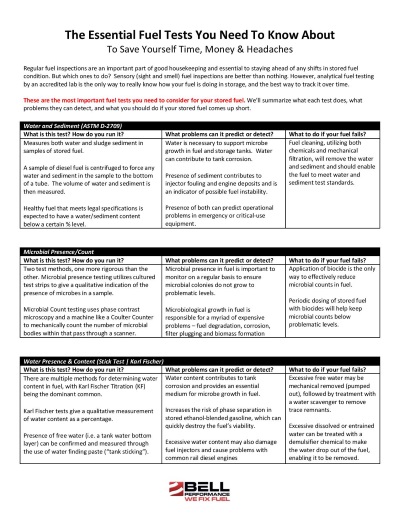

The biggest culprit in those situations is microbial buildup in those storage tanks. Microbes cause instability, they cause filter plugging. What they also cause is what they call microbe related corrosion. Within the industry it's abbreviated as MIC, microbially induced corrosion.

We mentioned earlier that microbes have a natural part of their biological processes, they produce acidic compounds. Those acidic compounds do exactly what you think they do, they attack storage tank surfaces and they start to corrode surfaces and components inside of that tank. There are cases where some types of bacteria have been known to eat through a 5 millimeter thickness of 3/16 grade steel in 1-2 months. That is an extreme case, but it is a documented case. It basically serves to illustrate what can happen, the kind of serious damage that these microbes can cause. This kind of damage is expensive. Anyone who deals with tanks knows that even if you have to replace parts inside of them, at least hundreds, if not thousands of dollars. It's not something that is a budgeted expected expense either. How did the changes to ultra-low sulfur diesel, how did it lead to microbe problems?

There are two inherent qualities of ultra-low sulfur diesel that have caused it to be more susceptible to these issues. First one is that is more what we call hydroscopic. It means it attracts water.

Sulfur was a natural biocide that tended to inhibit microbial growth. Microbes do not like being around high sulfur content. That is why it used to be when you had high sulfur and low sulfur diesel fuel, the conventional wisdom was, as long as you kept the water under control, you would not have to worry about microbial growth in those fuels.

Now, you take the sulfur out and there is virtually nothing in that fuel that is going to keep these microbes from growing and thriving in them. That is why if you have ultra-low sulfur diesel in the storage fuel tank, microbial problems have the potential to be huge, huge problems.

Old Stored Fuel Vs. Ultra-Low Sulfur Fuel

Okay. Let's cycle back for a moment. Remember we talked about those old storage tanks. The old storage tanks that have had fuel in them for years and years go back to the last time we had a major hurricane, a really active hurricane season. That was around 2003, 2004, 2005.

When hurricanes are coming, checking the backup fuel in the tanks tends to be more urgent than when imminent danger's not imminent. A lot of those tanks, they had fuel added to them back then. Because it was 2004, 2005, that was before the changeover to ultra-low sulfur diesel. What you've had is you haven't had any active hurricane season since ultra-low sulfur diesel was added to those tanks. What that means in practice is that a lot of those tanks have not had the attention paid to them that they need to.

Say next year the hurricane season is a little bit more active than it has been, a lot of those people are going to go and use those tanks, and unfortunately there's going to be some very serious issues because they haven't been checking them. The smart people, the smart businesses and the smart entities, they are going to be proactive and they're going to check out their tanks. They're going to make sure the fuel is up to standards, if they're not already directed to. We've got a few minutes left, so what we want to do in this last part of the webinar is, we spent a lot of time talking about the problems and why and all the little details about what exactly led up to those issues and the problems that those caused.

What we want to wrap up with is, we want to now talk about action. What do you do about these? These are the kinds of solutions that the industry has figured out for these problems. We're going to spend a few minutes just to go over these briefly and then we'll wrap up and take some questions at the end and we'll be out of here.

Fuel Instability

First problem, remember we talked about fuel instability. The problem was heavy fuel components, deposits of sludge in storage tanks and in engines, things like that, the cause being refinery cracking methods and also the actions of microbes in the fuel. Anybody who uses stored diesel is affected by potentially by this issue.

The recommended measure is that you have to treat the fuel when it is fresh. You have to treat the fuel with a stability treatment. There are a number of options out there that are effective. Some are better than others. If you are looking for a stability treatment, what you need is you actually need it to be a package of things. It's not one thing, it's actually 3 or 4 main things. It has to have an antioxidant in it which stops the oxidation reactions.

It stops those chain reactions. It has to have a dispersant in it that will keep sludge particles away, dispersed in the fuel and keep them from agglomerating and climerizing. It also helps if it has something to stop what they call a metal deactivator, which is, there are certain kinds of metals like copper that tend to be great catalysts for making fuel go bad, so a metal deactivator will neutralize the effect that that metallic exposure has.

Lastly, all of the good stability treatments out there in the marketplace are actually designed to be pretty cost effective by having what we have low treat rates. At least 1-2 thousand, if not 1-3 or more. If you happen to have something that claims to be a stabilizer and it wants you to put 1 - 1,000, you probably do not have one of the better ones.

Like we said, absolute #1 thing you have to do is add it at the beginning before the reactions are starting to take place. They will stop reactions, but they will not reverse reactions.

Preventing Cold Flow Problems

Second problem we talked about, cold flow handling problems, again caused by fuel gelling, paraffin wax dropping out because of the fuel getting cold.

Anyone in cold weather climate, any diesel user has the potential to be affected by this. Recommended measures, similar to stabilizers. The only thing you can do is treat the fuel with what they call the cold flow treatment and you have to do it before the fuel gets cold.

Fuel management professionals will know that their fuel tends to cloud up at a certain temperature. It's recommended to add a cold flow treatment before that happens. They work by basically keeping the crystals small and away from each other. That keeps the fuel from gelling. Addition to the fuel above the cloud point, which for most fuels is between 20-30 degrees Fahrenheit, that is basically how you do it.

Engine Design

One thing, last thing to say about this. We've mentioned about engine designs. Common rail diesel engines are pretty much standard now. Common rail diesel engines have smaller filter. They're higher pieces of technology and they stack smaller fuel filters because they want to keep absolutely everything out of that engine. While that's good for the engine, unfortunately for fuel gelling, that actually exacerbates the problem because the fuel filters plug more easily with smaller amounts of wax. The recommendations for treatment of fuel for fuel gelling are that if you thought that you didn't have to worry about it until the temperature got to 30, or let's say 25 degrees, now they're saying add 10 degrees to that and start worrying about it when it's 35 degrees.

That's an area where the change in engine technology is forcing human behavior to adapt to it if you don't want to have problems. It affects the sulfur level in diesel. Again, we talked about that this was basically not a performance issue. It was a liability issue, and so the only way that you can get around that is basically to dilute the fuel. Use the fuel if you can, but then keep adding ultra-low sulfur diesel until that sulfur level is diluted enough.

The reason we bring this up is because we have been asked. There are places like Fuel Polishers. There's a lot of fuel polishers out there. Some of them, in the effort to differentiate themselves from the competition, they make certain claims like, if you have fuel that has too high of sulfur content, we can polish that sulfur out of that fuel. It does not work that way. There's nothing that a fuel polisher can do through a mechanism or mechanical process that will reduce sulfur level if it's too high. The only thing you can really do is dilute the fuel or unfortunately get rid of it. That's really the only thing that you can do.

Continue reading Recent Fuel Changes and How They Affect You: Part 5

As a service to our customers, dealers and friends, Bell Performance hosts quarterly webinars on fuel topics of interest to their friends and their...

As a service to our customers, dealers and friends, Bell Performance hosts quarterly webinars on fuel topics of interest to their friends and their...

As a service to our customers, dealers and friends, Bell Performance hosts quarterly webinars on fuel topics of interest to their friends and their...