Choosing A Fuel Biocide For Your Farm: How Do Bellicide and Biobor Compare?

With the differences between farm fuels of today and the past, fuel biocides are an essential and necessary part of the arsenal employed by...

For fuel storage on farms, some kinds of storage tanks are better than others. The color, design, and tank material can all play a role in protecting the stored fuel quality.

Storing fuel on a farm requires careful consideration of safety, environmental, and regulatory aspects to ensure the storage facility is safe, efficient, and compliant with all relevant guidelines and laws. The "best" storage tanks for fuel in a farm setting would depend on the type of fuel being stored (e.g., diesel, gasoline, propane), the volume of fuel, and specific farm needs.

Having said all that, there are some general best practice advice and considerations on which tanks to choose.

Which one you choose can depend on whether the tank is above ground or below. Double-walled steel tanks are commonly recommended for above-ground storage of flammable liquids like gasoline and diesel because they offer durability and robust protection against leaks. The double-wall construction provides an extra layer of protection and can contain leaks if the inner tank fails. In underground storage, fiberglass tanks are often preferred due to their resistance to corrosion and leaks.

There are also differences in how steel vs. fiberglass plays a tank's role in protecting the fuel's quality in storage. There are differences between steel and fiberglass tank constructions that can affect diesel fuel's storage life and the management of microbial contamination. Both types of tanks have their advantages and disadvantages regarding these issues:

Corrosion: Steel tanks are susceptible to internal corrosion when water accumulates at the bottom, which is a common issue with diesel fuel storage due to condensation or water ingress. Corrosion can create an environment conducive to microbial growth, particularly at the water-fuel interface, where microbes (bacteria and fungi) find nutrients and water to thrive. This microbial contamination can lead to fuel degradation, filter plugging, and corrosion of the tank and fuel system components.

Fiberglass tanks are inherently resistant to corrosion, making them less likely to facilitate conditions that promote microbial growth due to corrosion. This can lead to a potentially lower risk of microbial contamination in properly managed systems.

Also, while steel tanks can be coated with protective linings to mitigate corrosion, they require diligent maintenance and monitoring to ensure the integrity of the lining and to detect corrosion early. Regular water draining and fuel treatment with biocides are necessary to manage microbial growth. Fiberglass tanks are generally compatible with diesel fuel, but the quality of the fiberglass and the construction of the tank must be appropriate for fuel storage to prevent any leaching or degradation that could affect fuel quality.

Speaking of heat, how does it affect fuel quality in storage? More heat energy leads to more and faster chemical oxidation reactions that are the cause of fuel breakdown. Most chemical reactions need energy to start them going. Hotter tanks provide more of that energy. Fuel deterioration can be minimized when fuel is stored at a cool, constant temperature. The more extreme the temperature swings and the higher the temperature, the faster fuel will deteriorate.

Evaporative losses vary with the type of storage, the type of fuel, and the steps taken to prevent evaporation. By painting the fuel storage tank with a reflective paint such as silver or white, evaporation losses can be reduced by up to 40% over a dark color storage tank.

Commonly, some equipment used on farms is seasonal and therefore it is important to properly treat the fuel that is left in equipment for long periods. Fuel life-extending stabilizers such as Bell Performance Mix-I-Go for gasoline and Dee-Zol Life for diesel fuel are extremely effective for this purpose. Fuel stabilizers slow down the process of fuel degradation, extending the useful life of the fuel, through the prevention of oxidation chain reactions. Simply put, if you keep the starting reaction from happening, the rest of the reactions in the chain (that are dependent upon the first one) won’t happen, and stored fuel maintains its quality.

Equipment that is idle for long periods should be stored with the fuel tanks either empty or full. Keeping a fuel tank full limits the amount of air in contact with the fuel which reduces the amount of water absorbed into the fuel.

The length of time fuel can be stored depends upon the condition under which it is stored. Generally, gasoline is recommended to be used within a month of purchase. Under ideal conditions where fuel is kept cool in underground tanks, gasoline would be expected to remain good quality for at least six months.

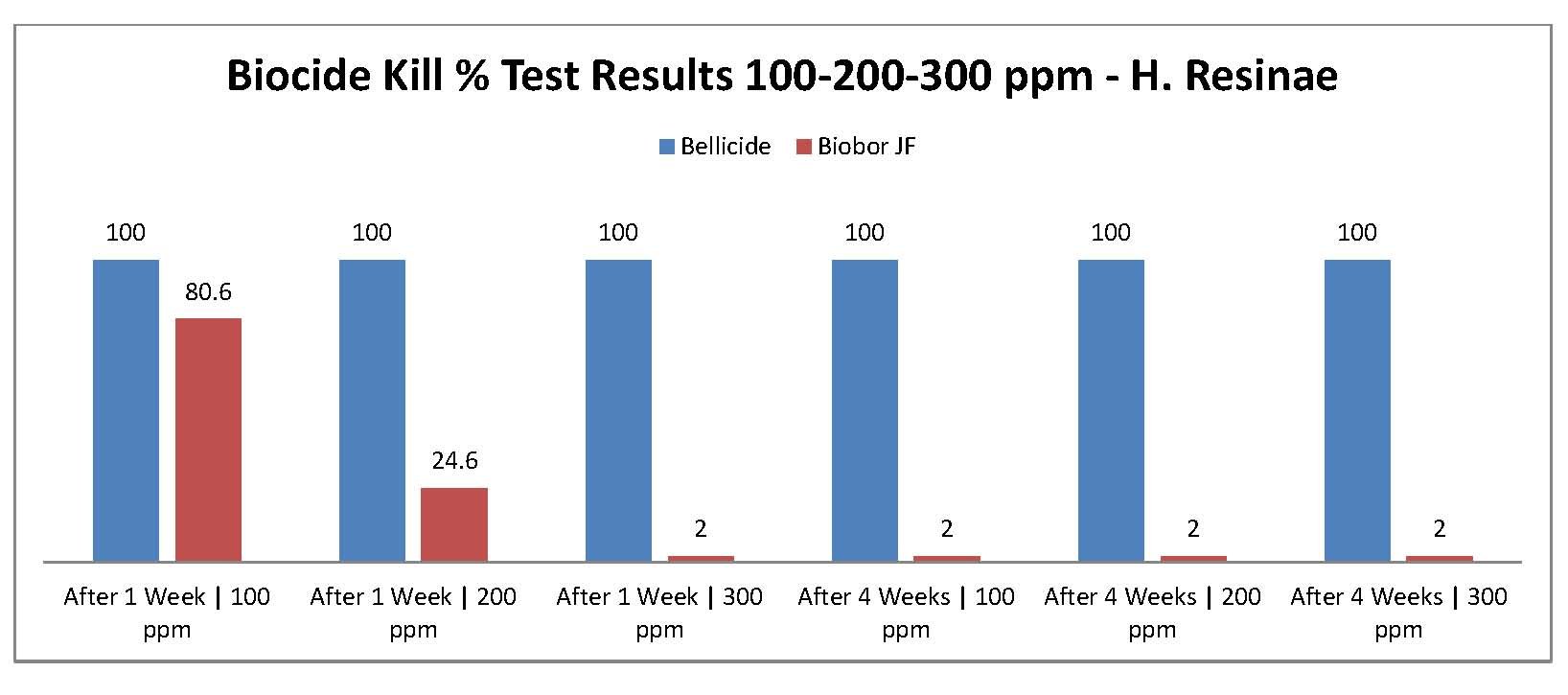

Diesel fuel kept clean, cool, and dry, can be expected to last longer, 6-12 months. Periodic filtrations and adding fuel stabilizers like Bell Performance Dee-Zol or Dee-Zol Life can extend the life of the fuel. It is also recommended to perform periodic fuel tank treatments with a biocide like Bell Performance Bellicide to prevent microbial growth. In this case, the preventive cost of treating fuel is small compared to the expense of cleaning fuel tanks and repairing the damage to equipment in which infected fuel is used or stored.

In these times of ever-rising fuel costs, it is more important than ever to follow the proper fuel storage recommendations and to use the appropriate fuel treatment products to extend fuel life. This is important because in many cases the increased production costs for crops cannot be recovered in the final sale price. It makes good financial sense to maintain stored fuel properly to minimize losses and maximize profits.

Don't Miss the First Post: Fuel Storage on the Farm: A Primer

With the differences between farm fuels of today and the past, fuel biocides are an essential and necessary part of the arsenal employed by...

Farms rely on fuel that is clean and free from contaminants. Certainly, it starts out that way when they buy it from, for example, their local co-op....

Whether you're talking about a farm fuel tank or any other kind (even home heating oil), it’s safe to say that any time you find “sludge” or biomass,...